In the rapidly evolving cannabis industry, AI and automation are making significant inroads—from cultivation to extraction, trimming, and packaging. Yet the question remains: can these technologies fully supplant human operators in bulk cannabis processing?

Automation’s Progress in Cultivation and Extraction

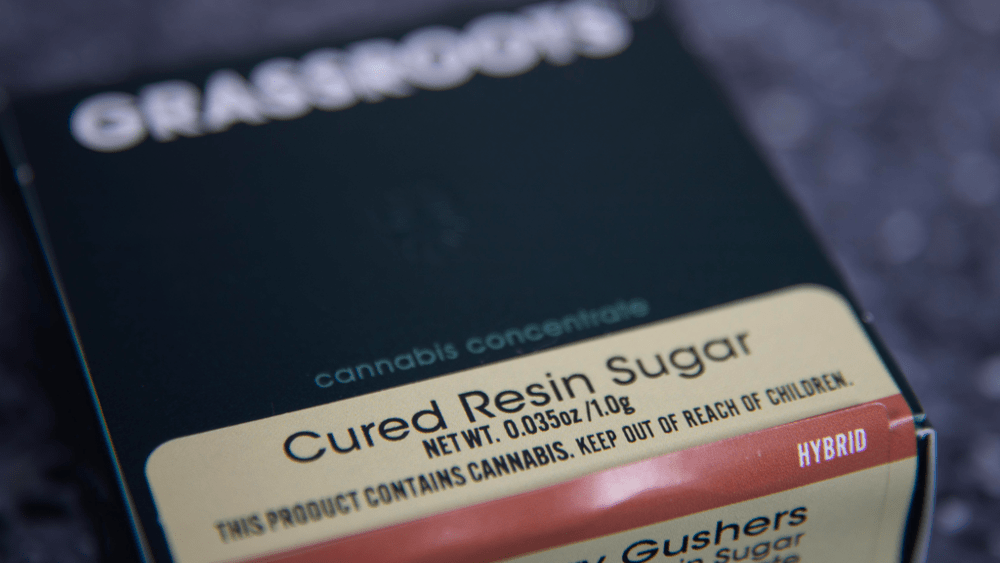

Industrial automation is already reshaping cultivation. Facilities use AI-driven sensors and environmental controls to maintain optimal humidity, lighting, irrigation, and nutrient delivery. Companies like Motorleaf and Grownetics leverage machine learning to detect disease early, adjust grow-room conditions dynamically, and predict yield outcomes. In extraction, AI monitors pressure, temperature, solvent ratios, and terpene profiles, allowing for automated optimization of batch consistency and safety—a stage that can now be executed by pushing a button.

Packaging and Trimming: Full Automation Feels Close

Processing post-harvest cannabis remains labor-intensive, but automation is catching up. Robotic “pick-and-pack” systems, equipped with AI vision, can pick pre-rolls, count jars, and load packages with faster, more accurate throughput and lower labor costs. Similarly, AI-guided trimming machines use camera vision to replicate human-level quality and speed—today matching manual operators, with continued improvement expected.

Human-Machine Collaboration: The Hybrid Reality

Despite rapid advances, full automation encounters limits. Cannabis processing is fraught with regulatory complexity and quality sensitivity. Every touchpoint carries contamination risks; eliminating human oversight entirely may introduce hazards. Historical precedents in meat processing and agriculture show that collaborative robots enhance throughput without removing human roles.

Labor isn’t solely about physical tasks—it also involves judgment. AI may flag bud quality or detect mould, but nuanced evaluation and exceptions require human intelligence. Moreover, AI systems require skilled staff for calibration, maintenance, and interpretation.

Economic Incentives vs. Adoption Barriers

Automation delivers lower OPEX, reduced waste, and predictable quality—critical in scaling operations and navigating labor shortages. Declining equipment prices and modular systems make partial automation accessible to medium-sized businesses. Yet challenges remain: high initial investment, rapid tech obsolescence, regulatory uncertainty, and the cybersecurity risks inherent to data-driven systems.

Workforce Impact and Future Roles

Will jobs vanish? History suggests no. Automation shifts labor into higher-value functions: system oversight, data analytics, QA, and compliance. Staff will spend less time trimming and packaging manually, and more time optimizing and maintaining smart systems. However, without upskilling efforts, a skills gap could hinder adoption and retention.

Enhancement, Not Eradication

At scale, automation is replacing human drudgery in bulk cannabis processing. From grow-room sensors to extraction systems, AI is removing repetitive labor. Yet total automation—especially in tasks requiring sensory judgment or flexibility—is not imminent. Most facilities will adopt hybrid human-robot systems. Humans will remain essential for quality control, compliance interpretation, and system management.

In bulk operations, computers and machines will dominate routine, high-volume tasks. Skilled humans, supported by AI, will steer the process—fine-tuning systems, monitoring anomalies, and ensuring regulatory and quality standards are met. Thus, rather than a wholesale replacement, the future is one of collaboration. The real question is not who will be replaced, but how quickly humans will evolve from manual laborers into smart operators of next-generation cannabis factories.